PVC Pipe Automatic packaging line|

PPR Pipe Automatic packaging line|

Coil Pipe Automatic packaging line|

Copper Pipe Automatic packaging line|

Steel Pipe Automatic packaging line|

Proximate matter Automatic packaging line|

Pipe fittings Automatic packaging line|

PVC Pipe Automatic packaging machine|

Steel Pipe/Welded Pipe Automatic packaging machine|

C Steel/Proximate Automatic packaging machine|

Keel Automatic packaging machine|

PPR Pipe Automatic capping labelling line|

Pipe Automatic bagging packaging machine|

Straight or Coil Pipe Automatic wrapping machine|

Other machines|

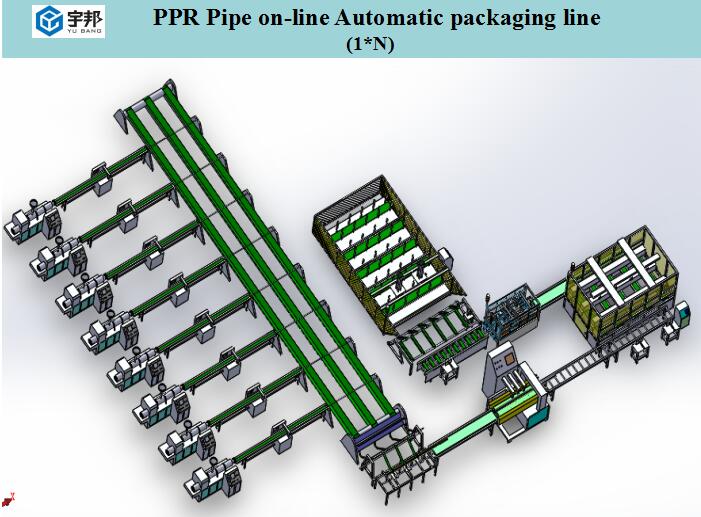

PPR Pipe on-line Automatic packaging line

PPR Pipe on-line Automatic packaging line

Suitable for: PPR pipe 20mm,25mm,32mm whole automatic packaging, PLC control, can connect several extruders.

Packaging process :

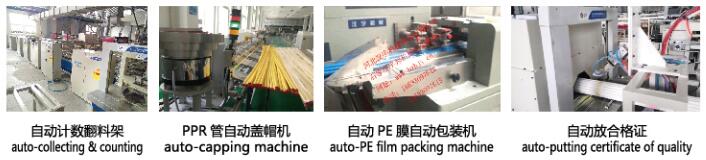

auto-receiving and counting,auto-transport,auto-sorting by machanical arm,auto packaging with bag,auto-classify,auto-bundling and putting certification,auto-bagging big bag,auto-stacking,auto-printing(specifications and type,diameter).

Features:

1. connect several extruders and setting the pipe type and number, suitable for different length pipe and different packing film

2. computer program and PLC control system, setting on the touch screen, easy operation

3. setting the pipe type, size , packing numbers, working shift and automatic create bar code.

4. no pipe cross, count accurately and no influence the spot test.

5. saving labor and improving marketing competitive capability.

Technical parameters:

Model: YB-BZX-01R

1. Suitable pipe:Ø 20、25、32、PPR pipe

2. Speed of small bag packing:30m/min

3. Out put of big bag packing:2packing /min

4. Palletizer :classify stacking

5. Body of machine material : SS41(A3 steel, spraying plastic)

6. Axle: S45C bearing steel

7. Roller bearing on the double-end (galvanize)

8. Engine cover SS41(A3 steel, spraying plastics)

9. Guide plate SS41(A3 steel, spraying plastics )

10. Electric power: AC,3 phase,380V,15KW 50HZ

11. Air consumption: 500NL/MIN(5-6kg/cm2)

Electric devise:

1. PLC: Mitsubishi

2. Touch screen: Delta

3. Low-voltage apparatus: Schneider

4. Sensor: Omron

5. Pneumatic component:AirTAC

6. Wiring pipes:trunking,soft tube protecting

7. Wiring:all note wire size

8. Mobility exclusive use cable and CABE CHAIN protection

PREV:PPR Pipe off-line Automatic packaging line

NEXT:None

NEXT:None

Product Catalogue

- PVC Pipe Automatic packaging line

- PPR Pipe Automatic packaging line

- Coil Pipe Automatic packaging line

- Copper Pipe Automatic packaging line

- Steel Pipe Automatic packaging line

- Proximate matter Automatic packaging line

- Pipe fittings Automatic packaging line

- PVC Pipe Automatic packaging machine

- Steel Pipe/Welded Pipe Automatic packaging machine

- C Steel/Proximate Automatic packaging machine

- Keel Automatic packaging machine

- PPR Pipe Automatic capping labelling line

- Pipe Automatic bagging packaging machine

- Straight or Coil Pipe Automatic wrapping machine

- Other machines